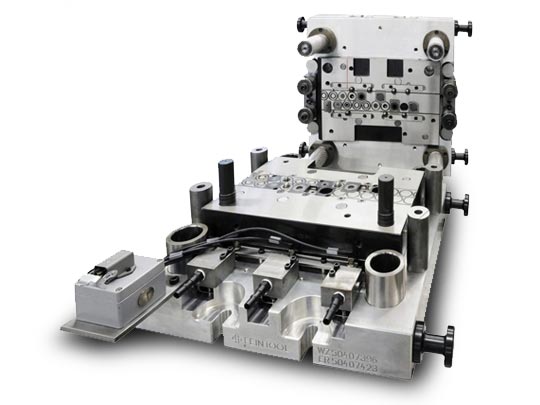

Our extensive experience in mechanical construction has lead us towards the design and development of Fine Blanking presses. At the heart of this system lies a highly refined and specialised technology, as the result of every pressing is a completely finished product - in size and shape - with no further mechanical work necessary.

The core of the press houses the highly precise machinery, made up of both fixed and moving parts, and functions via the components’ vertical movement – with centesimal accuracy - towards the moulds interposed between them.

We pay meticulous attention to the precision of each element’s pairing with its sliding, to the choice of materials, not to mention take great care during the workshop stages of development and the following thermal treatments, which ensure the maximum performance and long life of all parts subject to wear.

Of equal importance to our care for precision, is our decision to use hydrodinamic electronics, which allow us to construct presses at significantly greater speed.

Our technical office, thanks to the invaluable advice offered by specialised experts in the sector, has come up with numerous ways of updating and optimising the presses’ performance and productivity, including the older generation models. Indeed, with appropriate retrofits, we are able to increase many of the presses’ tonnages, thus making them more versatile and adaptable to various production needs.

So as to offer our clients as complete a selection of products for Fine Blanking as possible, we have recently incorporated all products and production under the BERTORELLO label. Therefore, the horizontal movement of the metal sheet is controlled and guaranteed by reel tape-winders, sheet roll straighteners, material feeding lines, a roll or jet lubrification system and waste-cutters installed at the end of the line.

With the aid of CAD three-dimensional design and planning systems, we are also able to perform structural analyses (FEM) to verify that the components subject to greater strain are of the correct size and shape, in accordance with the mechanical characteristics of the chosen construction material.

The amount and frequency of client demand, both on a national and international scale, has prompted us to form teams of specialised technicians tasked with the maintenance of the Fine Blanking presses, equipped with vehicles which have been transformed and repurposed as mobile workshops, aimed at quickly dismantling and transporting those parts in need of revision or repair.

We also possess a warehouse fully stocked with widely used and highly compatible spare press parts, for urgent, ‘Just in Time’ jobs.